Projects

Current projects

Energy harvesting from currents in breakwaters and generation of electricity and green hydrogen.

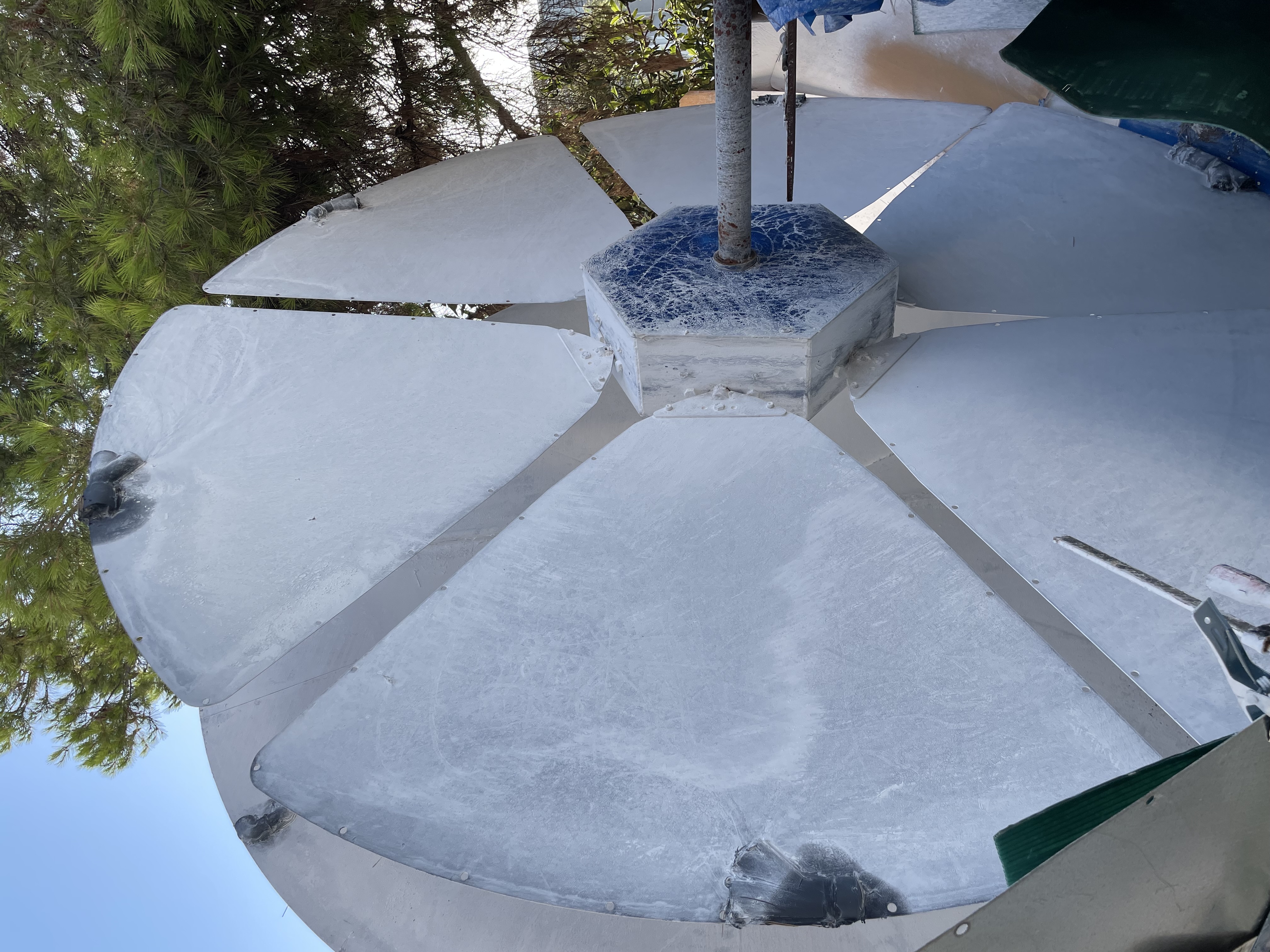

The RotaryWing project is developing an innovative system to generate electricity and green hydrogen by harnessing marine currents formed around port breakwaters. Using a Savonius-type rotor and an advanced-design hydraulic pump, it efficiently and sustainably converts the kinetic energy of currents into electricity.

This solution reduces both installation and generation costs compared to other marine energy technologies, while also minimizing environmental impact thanks to its compact design and the use of water as a hydraulic fluid (eliminating the need for polluting oils). RotaryWing opens new possibilities for decarbonization and green hydrogen production as a means of energy storage and fuel for ports, contributing to the energy transition and a more sustainable future.

The project is led and coordinated by ROTARY WAVE S.L., with participation from AIMPLAS (researching composite materials for hydraulic components), the Ceramic Technology Institute (ITC) (developing ceramic coatings for components exposed to marine corrosion), and the Institute for Energy Engineering (IIE) of the Universitat Politècnica de València, which is investigating green hydrogen production using the generated energy.

Wave energy generation using a breakwater-mounted device at the Port of Sagunto.

The RENMARINAS project is developing and will demonstrate an innovative wave energy generation system that will harness the motion of waves along the outer breakwater of the Port of Sagunto to produce electricity sustainably. The device features floaters connected to hydraulic pistons that convert wave energy into electricity, which is then generated onshore via turbines—contributing to port decarbonization and the broader energy transition. The project is currently in the design and manufacturing phase, with installation expected in early 2026.

The project involves ROTARY WAVE S.L. (marine energy technology development) and MECAFID (component manufacturing and machining), in collaboration with the Valencia Port Authority (APV), and is part of the RENMARINAS DEMOS program promoted by the IDAE.

Brine evaporation powered by photovoltaic renewable energy.

The EVAPSAL Project (Brine Evaporation with Photovoltaic Renewable Energy on a Test Bench), led by Rotary Wave S.L., aims to design, build, and validate an innovative system for the evaporation of liquid brine using only solar and wind renewable energy. The system avoids the release of salt particles into the environment and produces dry salt that can be reused in industrial applications.

The system is based on rotating discs soaked with brine that, through rotation, promote evaporation. These discs are powered by a Savonius wind turbine and photovoltaic panels that feed an electric motor. The device will also include automation via PLCs, environmental sensors, and an automatic solid salt collection mechanism.

Currently at TRL 4 (Technology Readiness Level), the project aims to reach TRL 6 through the development and validation of a semi-industrial prototype.

Three key research centers are involved in the project:

-

- AIMPLAS, responsible for developing plastic materials and “in situ” bearings resistant to salinity;

-

- The Miguel Hernández University of Elche (UMH), in charge of sensor integration and PLC-based automation;

-

- ITC-AICE, which will develop the ceramic protective coating for the salt collection system.

The EVAPSAL project addresses critical challenges such as sustainable brine management in inland or off-coast areas and reducing energy consumption in desalination, aligning with the principles of circular economy, decarbonization, and the ecological transition.

Past projects

Generation of energy from sea waves.

The project aims to develop a modular floating device capable of generating renewable energy from wave motion, specifically designed to operate in coastal areas or environments with limited access to the electrical grid. This innovative system converts sea movement into electricity through an oscillating structure equipped with internal mechanical components, offering a sustainable, low-cost, transportable, and marine-resistant solution.

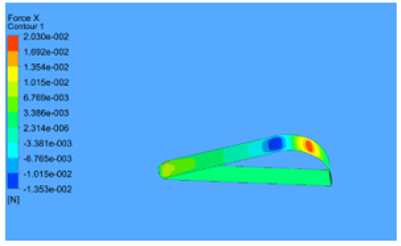

The project includes conceptual design, finite element simulations, selection of durable materials, prototype manufacturing, and validation in both laboratory and real-world conditions. The initiative is aligned with the goals of energy transition, blue economy, and decarbonization.

The device underwent a one-year intensive testing period in the coastal town of La Pobla de Farnals (Valencia) to assess its performance, structural reliability, and operational behavior in real sea conditions. During this period, continuous measurements were taken of key parameters such as energy capture efficiency, material durability, and mechanical stability of the system.

The results were highly satisfactory, demonstrating not only the technical feasibility of the device, but also its potential to be implemented as a real and effective solution for generating renewable energy from ocean waves.

10 kW Testing Platform for the Optimization of Wave Energy Harvesting Devices.

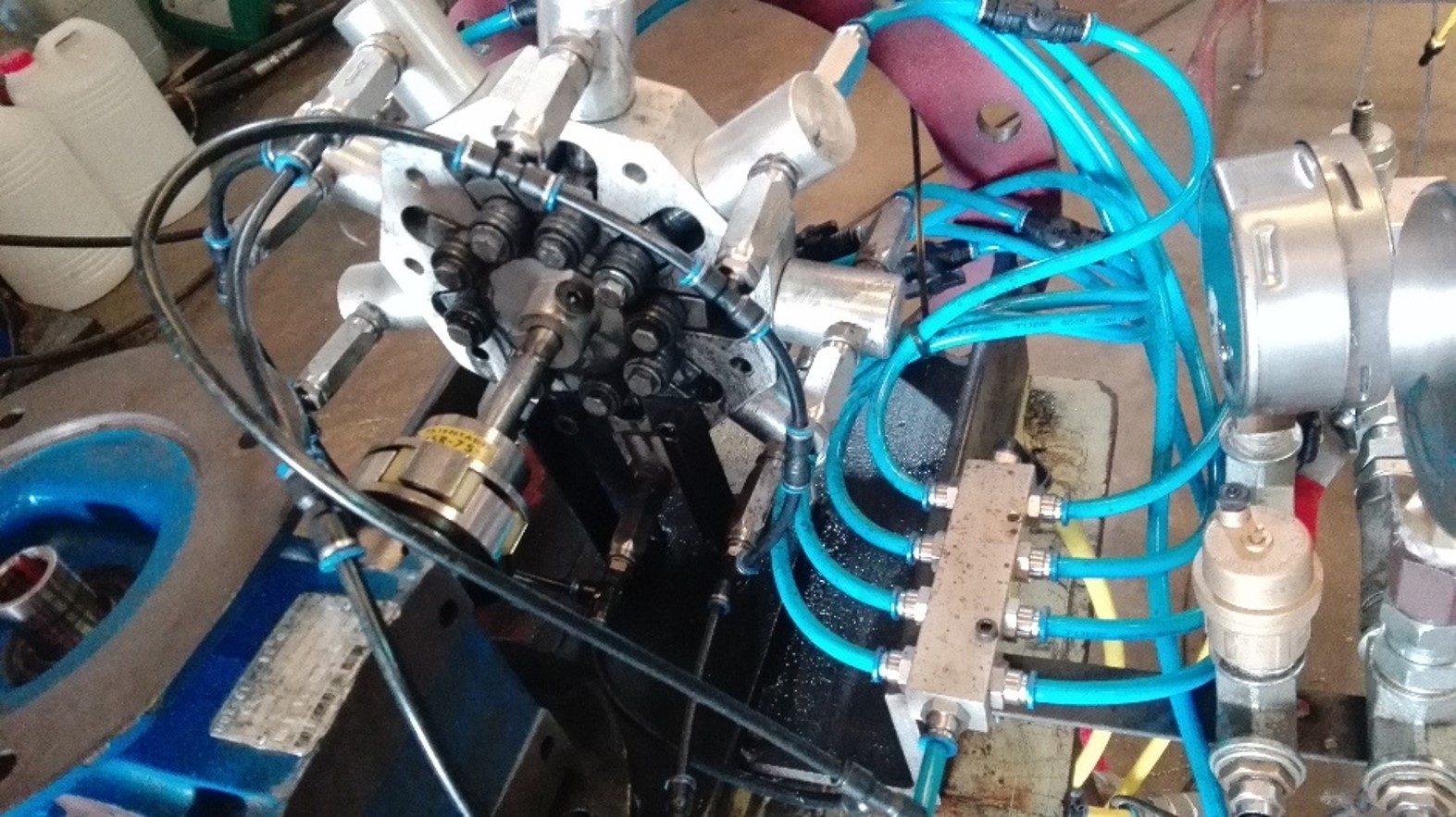

At Rotary Wave, we have developed a land-based test bench of up to 10 kW, which plays a key role in refining our wave energy generation technology. This test bench simulates wave motion onshore, allowing us to test, validate, and optimize the critical components of our Butterfly device—an innovative solution that transforms the power of the sea into clean and efficient electricity.

Thanks to this testing system, we are able to reduce the costs and risks associated with offshore trials, accelerate technological development, and ensure optimal performance before real-world deployment.

Funded by the CREATEC-CV 2016 program and developed at our facilities in Valencia, this project marks a decisive step toward the industrial feasibility of marine renewable energy. The test bench not only enhances our designs but also positions us as a leader in the development of sustainable technologies for harnessing ocean resources.

Development of Marine Energy-Based Electricity and Drinking Water Generation for Colombia.

At Rotary Wave, we are developing ENERGIMAR, an innovative project that harnesses wave energy to generate electricity and drinking water in a sustainable and affordable way. Designed for application in remote coastal areas, the project focuses on La Guajira (Colombia), where communities such as the indigenous Wayuu people suffer from severe lack of access to basic services.

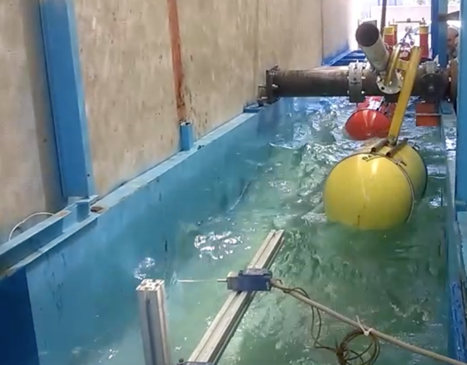

During the first phase of the project, we analyzed the needs of the region and designed a compact system composed of wave energy converters (WECs) and a power take-off (PTO) pump. Through advanced simulations and model testing, we have optimized the system’s efficiency, stability, and durability. All of this has been made possible thanks to our facilities in Valencia, which include an in-house wave channel and a dedicated test bench. ENERGIMAR represents a solid step toward a clean and accessible energy model, with real impact on the communities that need it most.

Optimization of Wave Energy Extraction by Floaters (ITE).

In this phase of our work, Rotary Wave focused on a key challenge to improve the efficiency of wave energy: the optimal design of floaters capable of capturing the sea's energy more effectively. Within the framework of the PIDI 2017 project, our goal was to develop a compact and accessible system to generate electricity and drinking water in remote coastal areas with limited resources.

To achieve this, we collaborated with the Technological Institute of Energy (ITE), which contributed its expertise in advanced simulation and hydraulic behavior analysis. Through CFD studies (Computational Fluid Dynamics) and experimental testing, we analyzed multiple floater shapes and configurations to identify the most efficient designs under various wave conditions.

The project also addressed the design of the power take-off (PTO) pump, a key component in the energy conversion process. This research reflects our commitment to the development of clean and functional technologies capable of providing real solutions to communities still lacking access to basic services such as electricity and clean water.

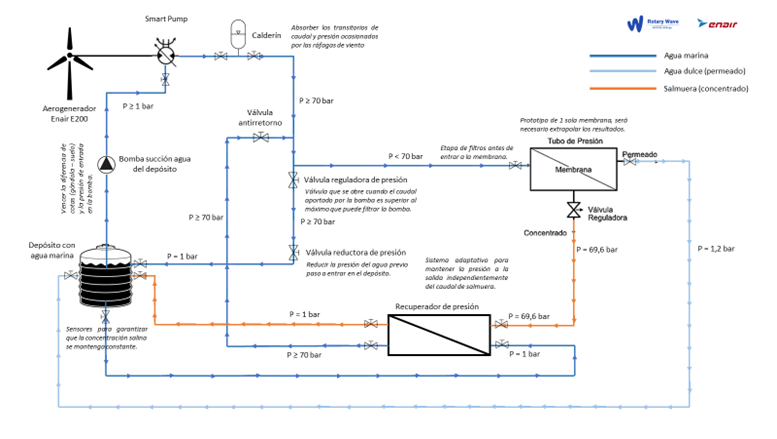

Seawater Desalination Without Electricity Using the E200 Wind Turbine and SmartPump.

With the goal of addressing one of the greatest challenges in isolated coastal areas—access to drinking water—Rotary Wave developed, within the framework of the PIDCOP 2018 project, a solution capable of transforming ocean energy into desalinated water ready for consumption.

The core of the project was the development of SmartPump, an intelligent hydraulic pump specifically designed to efficiently extract power from wave motion. SmartPump adapts in real time to changing sea conditions and is designed to integrate into seawater desalination systems, eliminating the need for fossil fuels or conventional electrical infrastructure.

This project was carried out in cooperation between Rotary Wave and Enair, a specialist in renewable energy, combining expertise in marine and wind technologies. It also included collaboration from the Polytechnic University of Valencia (UPV), which provided support in technical analysis, structural simulations, and result validation through laboratory testing.

Thanks to this joint effort, a robust, scalable, and sustainable solution was developed—one that enables the direct production of clean drinking water from the sea, using nothing but the power of the waves.

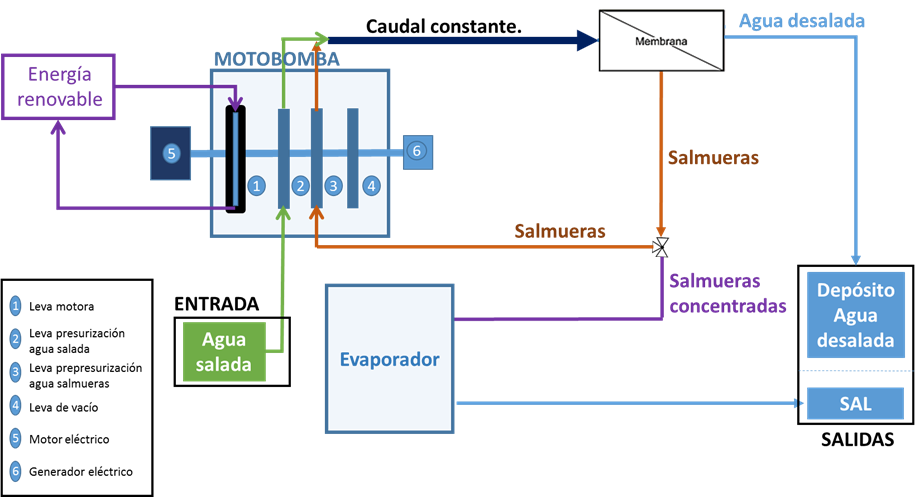

ECODESAL: A Direct Current Desalination Device with Zero Waste Generation.

ECODESAL is an innovative project by Rotary Wave S.L. that develops a closed-circuit desalination system (CCD) powered by 100% renewable energy (wind or wave), capable of producing freshwater and salt without generating brine waste. Its technology is based on a high-performance multifunction motor pump, designed with advanced materials resistant to salt and heat, which reduces energy consumption, eliminates waste, and facilitates installation both in coastal and inland areas. This system makes it possible to reduce the cost of desalinated water to €1/m³, eliminate up to 100% of brine, and extend the service life of the equipment thanks to the use of composites. In addition, it promotes the circular economy by reusing old wind turbines as an energy source.

The project involves the participation of technological centers and specialized companies such as AIMPLAS (research on resistant composite materials), ISYRIM (UPV) (design and validation of the CCD plant and energy balance), DISA (UPV) (development of control algorithms), IIE (UPV) (study of evaporation technologies), AQUALIA (plant integration and result validation), and MIRAPLAS (component manufacturing).

It also has the support and interest of key stakeholders in the water and agricultural sectors, such as Aqualia, Sacyr Agua, IMEDAGUA, and Acuamed (potential users and implementers of the technology), as well as AEDYR (sectoral support and dissemination), ASAJA, and FECOAM (representatives of the agricultural sector demanding sustainable irrigation solutions in water-scarce areas).

Wave Energy Conversion Test at the IH Cantabria Wave Flume.

The Blue Energy project aims to generate electricity in port environments by harnessing the power of ocean waves through an innovative floating system. The development is organized into four phases: initial testing in our own wave channel, validation in an external facility, simulation on a test bench, and real-world installation at the outer area of the Port of Castelló or another site along the Valencian coast.

One of the most important phases of the project took place at IHCantabria, where comprehensive wave channel tests were carried out to accurately calculate the forces the device is subjected to under various wave conditions—both during normal operation and extreme events. This data allowed the team to validate the structural design and optimize the system's durability and reliability.

The project involves several specialized collaborators: Rotary Wave (RW) as the coordinating entity responsible for design and development; Miraplas for the manufacturing of floaters and metal components; TYPSA for structural analysis and electrical design; the Polytechnic University of Valencia (UPV) for automation and control; and the University of Portugal, which contributes wave studies, environmental impact assessments, and electrical design input. The project also benefits from the support of mechanical workshops such as Mecafid, as well as the potential participation of an international electrical partner for energy generation and grid integration.

MATCH UP Project.

As part of the European MATCH UP project and within the framework of the València European Green Capital 2024 initiative, an innovative wave energy device was developed and installed at the Port of València, where it remained operational between 2023 and 2024. This initiative was funded by the European Union with the support of the València City Council, as part of a broader effort to integrate renewable energy into urban and port infrastructures.

The system, with a 20 kW capacity, is designed to harness wave motion and convert it into clean electrical energy. It consists of a floater that captures the wave energy, an articulated arm that transmits the motion, and a structural frame that keeps the entire assembly firmly attached to the breakwater without the need for riprap, simplifying installation and reducing environmental impact. The operation is efficient and mechanically simple: as the floater rises and falls with the waves, it activates hydraulic pistons that compress a fluid. This pressure drives a hydraulic motor connected to an electric generator, allowing the produced energy to be injected directly into the port's power grid.

This project was the result of collaboration between Rotary Wave, responsible for the design, control, and maintenance of the system; Proemisa, in charge of manufacturing and installation; and TYPSA, which contributed to the design verification through structural calculations. Thanks to this joint effort, the real potential of wave energy as a renewable source integrated into port environments has been successfully demonstrated.